Benefits of our solution

Investment in advanced abrasive blasting technology bringing significantly higher efficiency and savings in operating costs

Find out more

The savings results in remarkable increase of efficiency and fast return on investment

Find out moreWith the WISTA - SOLITON solution you can expect

up to 2x faster return on investment (ROI)

In some cases, SOLITON can save up to 50% overall on the entire blasting operation.

Saving operating costs

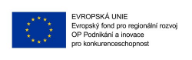

The technologies used in SOLITON solutions save up to 50% of your operating costs:

- 50% savings in energy consumption

- 50% savings on abrasivesrefills

- 2x higher operating performance

- At least 2x longer lifetime of consumable parts

Savings in operating costs lead to a 2x faster return on investment (ROI index).

Floor conveyor

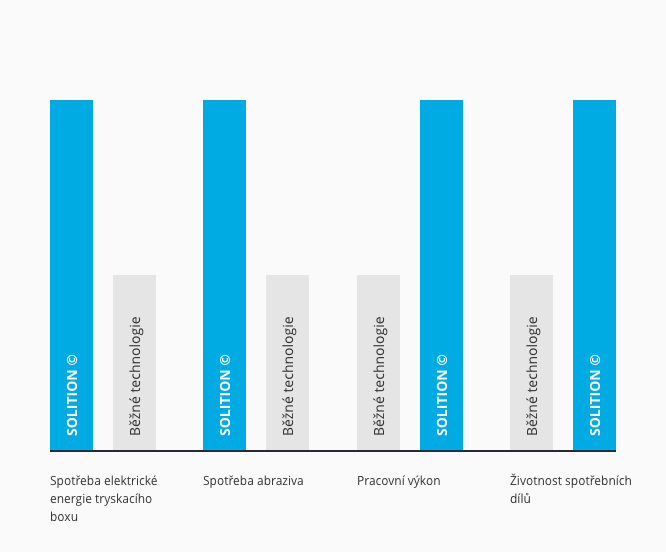

The technology used in SOLITON solutions saves up to 50% on your operation:

- Up to 75% more energy savings

- Up to 350% more power (up to 4kW)

- Up to 3 times longer lifetime of wear parts

... more information

Pressure losses

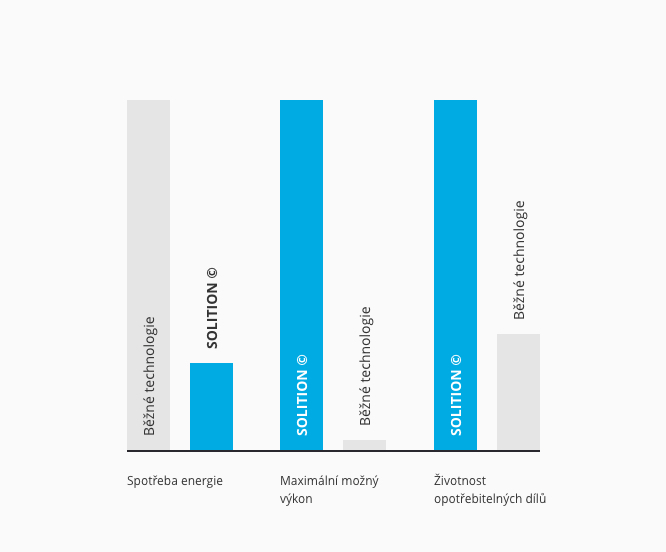

The technologies used in SOLITON solutions will save up to 50% of the cost of your operation:

- Up to 50% higher performance due to lower pressure losses

- Pressure losses from compressor to blasting nozzle with conventional technology freely reach 3bars

- The maximum possible pressure drop with SOLITION technology is 0,7 bar

Rating

What cannot be measured cannot be managed. A Technology audit is aimed at comparing the current state of blasting technology and the way it is operated. The data are then compared with the generally applicable rules of the blasting process and with the current state-of-the-art available technology. It is an ideal tool for identifying weak points in air blasting technology. It also serves as a basis for calculating the return on future investments to achieve higher blasting efficiency for company management.

What is SOLITON

The new generation of the successful concept of full abrasive collection blast box technology is characterized by easy installation, low operating costs, and long service life. SOLITON blasting halls are characterized by smaller process parts, economical operation, and higher performance. Thanks to a patented concept, it is possible to reduce energy by half. The intelligent control can adapt the performance of the conveyors to the amount of abrasive transported. ... more information

Savings

The amount of operating cost savings that SOLITON technology can save is directly proportional to the number of blasting shifts per day. In practice, the total savings typically exceed the purchase price of the entire technology. At WISTA, we know how to achieve efficient operation and are ready to design and implement the best solutions.

The operating cost savings with WISTA - SOLUTION technology can very often exceed the purchase price of the entire technology.

WISTA - SOLITON technology saves up to 50% of :

- Operators costs - typically 2 times the blasting performance

- Energy - economical drives for filtration, abrasive transport, low pressure loss.

- Abrasive - use of SCHMIDT (TX, USA) precise metering valves.

- Consumable parts - heavy duty construction and quality of parts used

SOLITON App

SOLITON App can also monitor the economics and subsequent efficiency of the blast hall over a selected time period. Here, some data has to be manually entered into the system, such as abrasive quantity, energy consumption, hourly operator wage, etc. Since 2018, a version is also available where the economics of individual jobs can be monitored, for example, what the cost per blasted chassis was, including the duration of the entire process.

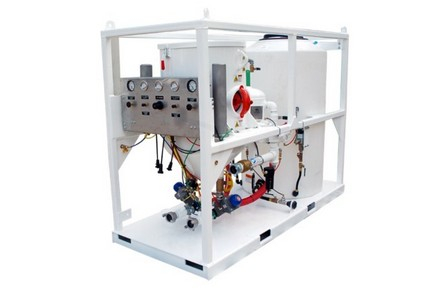

BLAREC

Compact blasting and recycling units are ready to be placed in blast boxes or mobile blast containers. Possibility of stand-alone function or connection to floor abrasive collection. The unit is manufactured as a complete assembly, including set-up and test, which speeds up installation. Thanks to Its small footprint, makes it very compact and easy to transport. BLAREC™ has a wide range of optional accessories. It also allows simultaneous blasting by two operators.

Cabins

Blasting booths in injector or pressure design are custom-made according to specific customer requirements. Standard manual blasting can, in some cases, be replaced by automatic or robotic blasting, which delivers significant productivity gains and a rapid return on investment.

Dry blasting systems

Depending on the blasting requirements, the pressure vessels of blast machines are divided into three basic systems. When the blast clamps are released, the pressure vessel holds neither pressure nor abrasive, it holds abrasive, or it holds both pressure and abrasive. For maximum productivity, you need to choose the correct option. ...more information.

Wet blasting

Applied wherever there is a requirement to reduce dust. The versatile Amphiblast abrasive blasting system combines proven and well-known SCHMIDT controls with innovative moisture injection technology. This creates a highly productive and easy-to-use combination of dry and wet blasting in one unit, with the possibility of rinsing and subsequent drying of the surface with compressed air. Here we have 4 functions in one unit. ... read more.